60% of all pipelines at the main gas separation unit of process line 3 of the Amur Gas Processing Plant have been tested

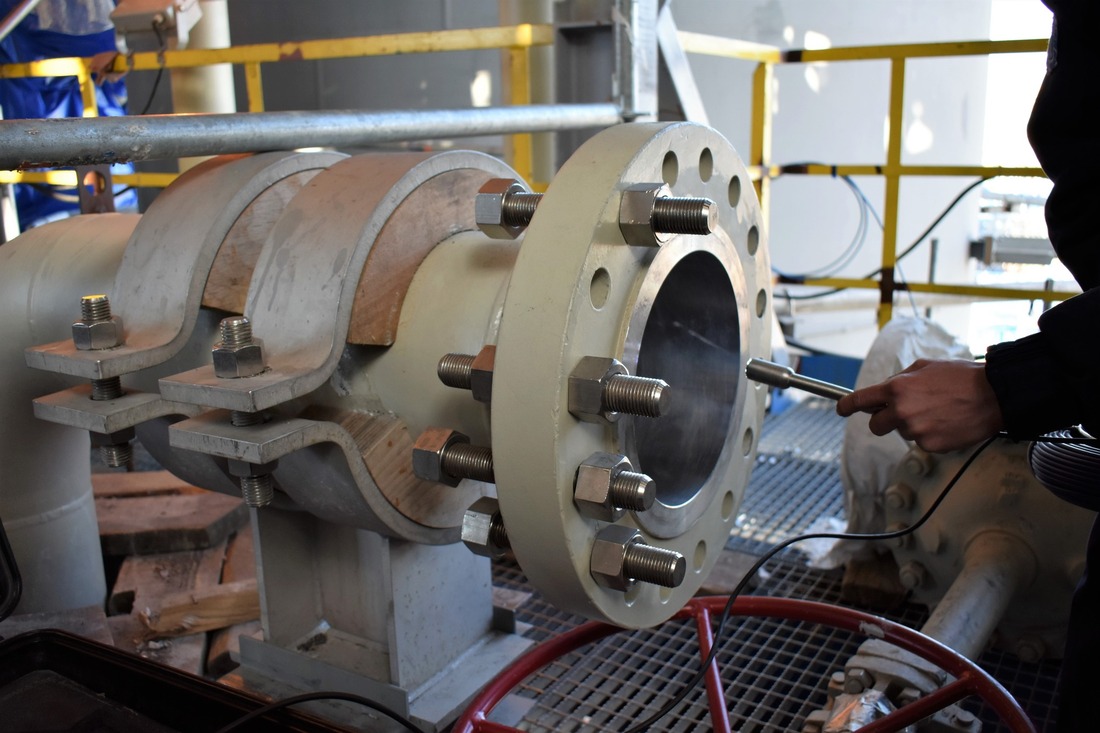

Pipelines are being tested for strength and leaks at the ethane and NGL extraction, nitrogen rejection and nitrogen and helium mix production of process line 3 at the Amur Gas Processing Plant. Possible defects in the pipeline materials and welded joints are identified this way during construction in order to ensure reliable operation of the unit under design conditions.Heat exchange equipment, components and assemblies, as well as shut-off and control valves at the gas separation unit require high purity of the media to ensure its reliable operation. For this reason, a baroscope survey, the purpose of which is to establish visually the absence of any mechanical impurities in the pipe cavity, is carried out after purging the pipelines with compressed air.

It is required to check 52 kilometers of pipelines for various purposes in total at the main gas separation unit of process line 3. Tests have been carried out on 32 kilometers of pipes: this makes about 60% of their total length.

Background:

The Amur GPP is to be one of the world's largest natural gas processing plants with its annual capacity of 42 bln of cubic meters of gas. Under full load, the Amur GPP is to provide annually around 2.4 mln tons of ethane, 1.5 mln tons of LPG, 200 tons of pentane-hexane fraction and 60 mln cubic meters of helium, which is highly demanded by high-tech industries. The main consumer of ethane and LPG from the Amur GPP is going to be Amur Gas Chemical Complex (joint SIBUR and China's Sinopec project).

To date, the first two lines of the plant have been put into operation, as well as the first helium purification, liquefaction and packaging plant.

Gazprom Pererabotka Blagoveshchensk LLC (member of Gazprom Group) is the investor, the owner and the operator of Amur GPP. Construction is managed by JSC NIPIGAS.

Enlarged photo (JPG, 631 KB)