Video gallery

Three of its process lines generate commercial gas products. Helium treatment, liquefaction and loading unit 1 and 2 operate in their normal process mode. High-purity liquefied helium (99,9999%) is shipped on a regular basis. Watch our video for details about the progress on process lines 4, 5, and 6.

Three of its process lines generate commercial gas products. Helium treatment, liquefaction and loading unit 1 and 2 operate in their normal process mode. High-purity liquefied helium (99,9999%) is shipped on a regular basis. Watch our video for details about the progress on process lines 4, 5, and 6.

Watch our new film whose heroes were yesterday's students and now the Amur GPP young employees. They each have a story, but they all share one thing: they work at one of the largest and most modern gas processing plant in the world. Some 40 percent of the Amur GPP employees are young people. Having graduated from universities and colleges in different Russian cities, more than 1,300 people have found work in the Russian Far East. Our heroes tell us about their lives and work.

A plant that has turned a small Russian Far Eastern town into a real industrial center of the region. The Amur Gas Processing Plant is one of the largest in the world. Its key product helium is in demand all over the planet. The consumers have already received more than five hundred tons of it. The supplies are only growing. At what extreme temperatures is this valuable product extracted, why can it boil, and what is the challenge for transporting helium? For details, watch the report of Vesti TV channel correspondent Evgenii Nipot.

Tests of process line 4 of the Amur GPP, the country's largest gas processing plant, are in full swing in the Amur Region. The plant will soon reach full capacity, and the region will become a global producer of helium. It is expected that 42 billion cubic meters of natural gas per year will be processed here. After the departure of foreign partners from Russia, Gazprom is coping with all stages of such a large-scale project on its own. For details, watch the report by Sergei Antsigin, NTV's correspondent in the Russian Far East bureau. https://www.ntv.ru/novosti/2818176

An unusual sculpture of an Amurosaurus was shown at Ekovesna festival in Svobodny park. The town hosted the festival for the first time. Ten playgrounds were set up in the park for the festivities. On one of them, the employees of Gazprom Pererabotka Blagoveshchensk together with the guests of the festival installed a dinosaur figure made from woodworking waste.

Electric power infrastructure for process line 4 at the Amur Gas Processing Plant (GPP) is ready for operation. Power is now supplied to its facilities in line with Rostechnadzor permit. Individual tests and cold runs of the electric motors at the main gas separation unit have been completed. Individual tests of the standby diesel power plants of line 4 are nearing completion. They ensure power supply to the plant in case of any power outages in the regional grid. Total estimated electrical power consumption of all facilities of Amur GPP process line 4 is comparable to the power needed to supply more than one and a half thousand private residential houses — in other words, a large village.

The key result for the Amur GPP in 2023 is that half of the plant's production facilities were put into operation, with two out of three helium units started up and now in operation. Isothermal containers with liquid helium of the highest degree of purification (99.9999%) are shipped to Russian and foreign consumers on a regular basis. This is the result of significant efforts taken last year by the process teams of the plant and its contractors. Watch the video to learn about our activities in 2023.

More than one hundred iso-containers with high-purity liquefied helium were shipped to consumers from the Amur GPP in 2023. One half of the plant's production facilities has already been put into operation. This is the main result of the year for the Amur GPP employees. Details are presented in the video of Svetlana Dyuzhova, correspondent of Amur state television broadcasting company.

Helium is extracted from natural gas at the Amur GPP using some unique cryogenic equipment. At the final stage, it transforms from gas into liquid at ultra-low temperatures. See how it happens in the report by GTRK Amur correspondent Svetlana Dyuzhova.

Gazprom Pererabotka Blagoveshchensk employees took part in a charity fair to help children in Svobodny. This event was held in the plant administration building of the Amur GPP. Everyone could buy handicrafts made by children with disabilities and their parents of the association We Are Together, pupils of the Svobodny correctional orphanage and the social shelter, and children of the Svobodnensky district. The employees of Gazprom Pererabotka Blagoveshchensk (investor, owner and operator of the Amur GPP) have managed to collect more than 250,000 rubles during the New Year's Eve charity fair.

Commercial products and liquefied helium are being generated on process line 1. The main gas separation unit is undergoing the commissioning preparations on process line 2. Hot trial run of heat pump run in a loop completed. Hot commissioning of both Ladoga GPU 32 completed. The main unit operates in its normal process mode and commercial products are being generated on process line 3. Hot commissioning is in progress at helium treatment, liquefaction and loading unit 2. Watch our video for details about the progress on process lines 4, 5, and 6.

Amur GPP process line 1 was put into commercial operation. Commercial products under design specifications were generated, including high-purity liquefied helium (99.9995%). Loop and functional tests finished on process line 2. The unit for dehydration and removal of impurities is undergoing the commissioning preparations. Process line 3 switched to its process mode. Commercial products under design specifications were generated. Hot commissioning is in progress at helium treatment, liquefaction and loading unit 2. Electrical works, pre-assembly and tests of pipelines are in progress at the natural gas liquid purification and gas fractionation units. Watch our video for details about the progress on process lines 4, 5, and 6.

Svobodny hosted the event with much eclat at Olimpiysky stadium on October 7. Both adults and children of different ages showed their achievements in various athletic disciplines. The Amur GPP employees and their families competed in 100 and 200 meters dash, volleyball and basketball, trampolining, family relay and other contests. Children and teenagers were so excited to play laser tag and paintball, where they could show their accuracy. This event gathered more than two thousand people and gave the employees an opportunity to actively and healthily spend their weekend together with their families.

The Amur GPP job fairs held by Gazprom Pererabotka Blagoveshchensk (the investor, owner and operator of the Amur GPP) have been attended by more than 100 people in Orsk and Orenburg this week. «We select regions with operating oil and gas processing enterprises, such as the Orenburg Region — to name a few. Some 50 dedicated experts submitted their applications and CVs within two days, so we are shortly expecting a constant flow of the applicants from the Orenburg Region,» said Nikolay Chulkov, Head of the Hiring Department of Gazprom Pererabotka Blagoveshchensk LLC. The job seekers said that they were interested in working at the modern plant with career opportunities, high salary, vast benefits, and comfortable corporate housing. Residents of nearby towns and regions were also interested in getting jobs at the Amur GPP. Professionals from Buzuluk and Salavat attended the Orenburg job fair — to name just a few.

Two isothermal containers were filled with helium at treatment, liquefaction and packing unit 1 of Amur GPP process line 1 for the first time on September 5. They are now on their way to the consumers. So called «solar» gas is liquefied at ultra-low temperatures close to that of outer space — negative 269 degrees Celsius. Amur GPP produces valuable gas with 99.9999% purification degree being the highest. It accumulates in the liquefied helium storage tanks at the unit. Isothermal containers are placed on the scales located under the storage tanks. Liquefied helium is loaded into them by gravity via special sleeves. It is then transported with KAMAZ-5490 NEO truck tractors. They use liquefied natural gas as motor fuel. Two cryogenic vessels enable an up to 1,400 kilometer haulage without refueling while fully loaded. Gazprom Helium Service is in charge of transportation.

A thousand balloons filled with helium from the Amur GPP became the main decoration of Svobodny holiday called First of September Commotion.

Employees of Gazprom Pererabotka Blagoveshchensk acting as the investor, owner and operator of Amur GPP, congratulated the students of school 1 and the Amur Technical College with the beginning of the school year. These educational institutions are the partners of the company.

Blagoveshchensk hosted the international Run toward the Dream marathon. It was attended by some 40 employees of Gazprom Pererabotka Blagoveshchensk (the investor, owner and operator of the Amur GPP). Headed by Chief Engineer and First Deputy Director General Danis Fayruzov, a team of seven employees ran a half-marathon of 21.1 km. Chemical engineer Elena Nikhaychik is the only woman who had courage to run such a significant distance. Aleksandra Ishpayeva and Kseniya Zykova competed alongside men in a 10 km race. The 5 km distance became the most popular. Having won the bronze among the 50–59 and 40–49 year olds, Dmitriy Matrenin (26.19 min) and Viktor Shorokhov (20.24 min) showed the best results. Irina Matrenina (5 km in 32.05 min) showed the best result of the team among the female employees. She is top three women of her age. Many employees took part in the race with their families. These were the spouses Elena Nikhaychik and Aleksey Nikhaychik, Irina Matrenina and Dmitriy Matrenin. Gazprom Pererabotka Blagoveshchensk LLC team ran a total distance of 327.7 km. All runners were awarded the finisher medals.

Svobodny celebrated the traditional Svobodny — Everyone's Welcome! festival of national cultures last weekend. It gathered about a thousand people. They tries Turkish kebab and Belarusian krupnik stew in a single venue. Russians and Kyrgyz, Uzbeks and Chinese, Turks and Belarusians, Evenks and Tajiks presented their culture and cuisine here. Amur Regional TV crew also visited the festival. Watch the report from Amur Regional TV. https://www.amurobl.tv/news/obshchestvo/2023-08-16-festival-natsionalnykh-kultur-proshyel-v-svobodnom

Svobodny residents had a chance to try real Uzbek pilaf, see more than a hundred Russian samovars and fly over the Amur GPP. The town enjoying special attention of the Russian President celebrated its 111th birthday. The main part of the event was the traditional Svobodny — Everyone's Welcome! festival of national cultures hosted by the Public Council of the gas chemical cluster plants and supported by the Administration of Svobodny and the Ministry of Culture and National Policy of the Amur Region. Anzhelika Pavlova, Vesti — Amur Region, reports. https://gtrkamur.ru/news/2023/08/14/322476

Svobodny hosts traditional Town Day festival of national cultures Svobodny — Everyone's Welcome! Thousands of Svobodny residents and guests of the town have come to the festival. Concert, workshop and international cuisine events were held in the city centre despite the bad weather. Everyone had a chance to taste dishes cooked by representatives of the ethnic communities, including employees of Amur GPP and Amur GCC contractors from Turkey, Kyrgyzstan, Uzbekistan, and China. Amur Cossacks cooked their traditional kulesh porridge while EMERCOM employees offered dishes of Belarusian cuisine. Entertainment included workshops of national crafts and traditional arts, as well as Flight Over the Amur GPP, a VR tour to one of the largest gas processing plants in Russia. The festival guests played games of different nations. Performance groups and ethnic communities of the Amur Region offered their shows on stage. Students of Svobodny children's art school showed the Amur GCC through the Eyes of Young Artists exhibition of paintings. Everyone had a chance to take photos in the Amur GPP and Amur GCC project booths.

See what the sphere tanks of the Amur GPP look like from a bird's-eye view. Just imagine: a city bus can easily fit inside each giant sphere. Impressive, right? The tanks are designed to store our plant's products: propane, butane, natural gas liquids, and pentane and hexane fraction. Watch our video to see four tanks in area 3 of the plant's tank farm. They are fully ready for operation and undergoing hot commissioning around the clock. Each sphere tank weighs more than 400 tons: its diameter is 16.6 m, and it holds 2,400 cubic meters instead of the standard 600 cubic meters. The oversized tanks helped reduce metal consumption of the tank farm and the Amur GPP footprint.

Process line 1 and 3 of the Amur GPP sees the activities to improve the safety systems of the licensed units complete. Testing of automated fire alarm, fire fighting and gas detection systems is complete; installation and commissioning of ultra-sensitive dynamic laser system for detecting methane leaks are complete; installation and commissioning of an advanced process video surveillance system are complete. Gas fractionation and NGL purification unit 1 is prepared to receive the product. Revision and maintenance of the process pipelines are nearing completion at line 2. Installation of electric heating tracing of pipelines at the licensed units of line 4 as well pre-commissioning are in progress. Cold run of the booster compressor station 4–110V is complete. Fire protection works are underway. Oil flushing of the equipment is in progress on process line 5. A total of 4,305 tons of steel structures have been installed on line 6. Installation of the roofing sandwich panels has been completed on the compressor station.

It was attended by more than twenty employees. They cycled about 12 km through the suburb area of Svobodny. The bicycle race was organized by the Council of Young Scientists and Professionals at Gazprom Pererabotka Blagoveshchensk (the investor, owner and operator of the Amur GPP). «The event is dedicated to promoting the healthy lifestyle and developing sports traditions,» said Anton Popov, participant and co-convener. Two-wheeled bicycles weighing no more than 17 kg were allowed to participate in the event. All the competitors provided the medical certificates of absence of contraindications.

Process line 1 and 3 of the Amur GPP are seeing the activities to improve the safety systems of the licensed units. Testing of the automated fire alarm, fire fighting and gas contamination detection systems is complete. Installation and commissioning of an ultra-sensitive dynamic laser system for detecting methane leaks are in progress. Installation and commissioning of an advanced process video surveillance system are nearing completion. Preparations for starting up the heater for drying the lining, as well as individual tests of dynamic equipment are in progress at NGL purification and gas fractionation unit 1. Revision and maintenance of the process pipelines are nearing completion at line 2. Installation of electric heating tracing of pipelines at the licensed units of line 4 as well pre-commissioning are in progress. Pre-commissioning on auxiliary systems is underway at Ladoga gas pumping units 7 and 8. High-voltage tests of transformers and relay protection circuit breakers are completed at the unit for dehydration and removal of impurities (power center). Rostechnadzor's permit for power supply has been obtained. Line 5 is seeing oil washing of the equipment and commissioning works at the diesel power plants. A total of 4,297 tons of steel structures have been installed on line 6. Roofing sandwich panels are being installed on the compressor station.

Employees of Gazprom Pererabotka Blagoveshchensk told about job vacancies at the Amur GPP in Syzran, Novokuibyshevsk, Samara, and Tolyatti. Industrial job fairs of the investor, owner and operator of the Amur GPP were held in the employment centers of the cities. They were attended by more than 100 applicants with professions in demand at the new plant. First of all, these include operators of process units, process pumps and pumping units. Potential candidates had the opportunity to have an interview with the heads of the Amur GPP production units directly at the events, learn about the specifics of employment in the project, have their questions about employment conditions answered. The visitors also watched some video materials about the plant itself, as well as about the new residential district with comfortable company-offered housing is provided for the Amur GPP employees.

Process line 1 and 2 of the Amur GPP project (managed by NIPIGAS) sees completion of improvements to the safety systems of the licensed units. Testing of the automated fire alarm, fire fighting and gas detection systems is complete, among other things. Installation and commissioning of an ultra-sensitive dynamic laser system for detecting methane leaks are in progress. Installation and commissioning of an advanced process video surveillance system are nearing completion. Mechanical completion of the main gas separation unit and helium unit 2 is achieved on process line 3. Pre-commissioning and commissioning are underway. Additional leak tests, installation of electric heating systems of the pipelines, and pre-commissioning of electrically operated valves are in progress on process line 4. Pre-commissioning is underway at Ladoga gas pumping units 7 and 8. Testing of a packaged modular compressor at unit 8 is complete. Electrical works in the substation buildings are in progress on process line 5. Welding and assembly of the oil system, drainage and fire-fighting pipelines at Ladoga gas pumping unit 10 are complete. Welding and assembly of the process pipelines commenced on the booster compressor station. 4,285 tons of steel structures were installed on process line 6.

Process lines 1 and 2 of the Amur GPP sees the activities to improve the safety systems of the licensed units complete. In particular, the installation and commissioning of an excess number of stationary gas pollution monitoring sensors, sensors for monitoring the axial force of the fastening elements in the cryogenic flange connections are now over. Additional fire extinguishing system equipment has been installed on the cold box of the main gas separation unit at process line 3. Installation of an ultra-sensitive dynamic laser system for detecting methane leaks, as well as installation and commissioning of an advanced process video surveillance system have been completed. Process line 4 is seeing the installation of the electric heat tracing systems for pipelines, final assembly of the static equipment, calibration of the safety valve, and loop testing of the instrumentation. Pre-commissioning of the exhaust vents and subsystems of auxiliary pipelines and oil flushing are in progress at Ladoga gas pumping units 7 and 8. Assembly, welding and installation of pipelines and electrical works are in progress at the unit for dehydration and removal of impurities. Process line 5 is seeing the strength and tightness tests, pipeline blowdown, and re-assembly of pipelines. Commissioning of the indoor switchgears, electrical works at the substation, installation of the ventilation systems in the compressor room and electrical works are in progress at the substations of the NGL/nitrogen recovery and helium concentrate unit and helium fine purification, liquefaction and filling units. Process line 6 is seeing the installation of a fire-proofed screen made of sandwich panels and steel structures.

Gazprom Pererabotka Blagoveshchensk (investor, owner and operator of the Amur GPP) presented the existing open positions at the job fairs in Bashkortostan. The presentations were held jointly with the Employment Centers in the cities of Neftekamsk, Sterlitamak, and Salavat. Visitors to the fairs had a chance to get acquainted with the Amur GPP project, employment conditions and jobs, including the following professions: operators of compressors and pumps, as well as process compressors, operators of process units, process unit repairmen and emergency recovery professionals, and many others. Over two hundred applicants consulted directly with the heads of the production units and the recruitment department of the Amur GPP. About a hundred people filled out their questionnaires and passed the preliminary interviews. The greatest interest was shown in the jobs related to main production, mechanical repair shop, and power departments. Visitors to the job fairs saw some videos about the status of the Amur GPP project, natural gas processing, sales helium production, as well as about the current activities of the employees from various departments.

Lighting is mainly of the LED type, and most of it is Russian-made. Operational lighting has already been installed at the first four out of six process lines of the plant, as provided for by the equipment lighting design for the plant operation. Operational lighting is easy to recognize by the colder light. See the fascinating illumination of the Amur GPP in our video.

Pre-commissioning and commissioning are in progress on the Amur GPP process lines 1 and 2. Pre-commissioning and commissioning are in progress at the main gas separation unit on process line 3. Leak testing, oil flushing and installation of electric heating systems of the pipelines are underway on process line 4. Tests of the lifting mechanism and preparations for cold run of compressor are underway at Ladoga gas pumping units 7 and 8. Process line 5 is seeing the strength and tightness tests of the installed process pipelines. Electrical works are in progress at substations of NGL/nitrogen recovery and helium concentrate unit and helium fine purification, liquefaction and filling unit. Process line 6 is seeing installation of the main steel structures.

More than 200 employees of Gazprom Pererabotka Blagoveshchensk (the investor, owner and operator of the Amur GPP) took part in the event marking PJSC Gazprom's 30th anniversary. The President of the Russian Federation Vladimir Putin congratulated the company on its anniversary via videoconference. Heads of Gazprom Group's seven subsidiaries (operating across the country) and Yuri Lebedev, Director General of Gazprom Pererabotka Blagoveshchensk LLC, among them spoke about their companies' operations. We bring to your attention a fragment from the solemn event which was broadcast on Russia-24 TV channel.

Pre-commissioning and commissioning are in progress on process lines 1 and 2 of the Amur GPP. With the drying and inertization operations over, process line 3 is seeing the completion of insulation of the shut-off and control valves at the main gas separation unit, and pre-commissioning is underway there. Installation of the electrical heat tracing on the pipelines and installation and pre-commissioning are underway at Ladoga gas pumping units 7 and 8 on process line 4. Process line 5 is seeing the strength and tightness tests of the process pipelines. Installation of the main steel structures is in progress, installation of hangars has finished at Ladoga gas pumping units 11 and No. 12 on process line 6: the units have been installed on their foundations, removed from their containers and passed the incoming inspection.

Watch this video that sums up the results of 2022 and shows the construction site of one of the world's largest gas processing sites month after month from January to December.

Solemn ceremony of the six houses with 195 apartments welcoming their residents was held today in Alekseevsky district in Svobodny. Yuri Lebedev, Director General of Gazprom Pererabotka Blagoveshchensk LLC, took part in the event. This is the fourth batch of residential buildings for the employees of Gazprom Pererabotka Blagoveshchensk (acting as the investor, owner and operator of the Amur GPP). A total of 24 residential buildings with 780 comfortable apartments are occupied in this district for the gas company employees by late December. In addition, 10 more residential buildings have been built for the employees of the Amur GPP and Gazprom group companies with 710 apartments as infill development in Svobodny. The year 2023 is planned to see the construction of a daycare facility for 350 kids with a swimming pool, a school for 900 students, a hospital, a department store, and an apartment hotel with 158 rooms in Alekseevsky district. Construction of an all-purpose sports complex and an entertainment center will also begin next year.

Vladimir Putin, President of the Russian Federation, and Alexey Miller, Chairman of the Gazprom Management Committee, took part in the event via a conference call. The Kovyktinskoye field has the largest gas reserves in eastern Russia. It is the key field for the Irkutsk gas production center and, together with the Chayandinskoye field in Yakutia, forms the resource base for the Power of Siberia gas pipeline. The top-priority infrastructure facilities for full-scale production are ready at the Kovyktinskoye field. They include, first of all, the comprehensive gas treatment unit No. 2 (CGTU-2), which is a high-tech complex with a total area of 800,000 square meters and an annual capacity of more than 6 billion cubic meters of gas. The facility receives hydrocarbons from the field's production wells and provides the treatment of the hydrocarbons to remove water, as well as mechanical impurities and other solids from them in order to ensure that the quality of gas complies with the stringent requirements set by Gazprom's standards. A high level of automation based on domestic systems makes it possible to manage the production processes remotely and ensures complete safety.

The last module of the cold box was installed on the Amur GPP process line 5. This equipment is an important element of the complex of cryogenic technological equipment and is intended for cooling the natural gas entering the plant before being fed to the gas separation columns. The feed gas cooling unit consists of seven modules which are all different sizes, weighing from 70 to 280 tons. Total weight of the installed equipment of the cold box is about 1,400 tons, its height is more than 77 meters. A heavy-duty concrete base has been prepared for assembling the unit. The modules are assembled into a single unit using a crane with a lifting capacity of 1,600 tons.

The sixth pair of Ladoga gas pumping units 32 has arrived at the Amur GPP. They will be installed on the sixth process line of the plant in the near future. Sites and hangars for the placement of the units are being built here around the clock and concreting of the foundations has already been completed. About 70% of the main steel structures of the hangars have been installed. Ladoga gas pumping units 32 are manufactured in Saint Petersburg at Nevsky plant. The units overcame the main route with a length of more than 8 thousand kilometers to the Amur GPP by rail in just 27 days, which is a record time. Delivery on this route took up to 85 days in previous years. Ladoga gas pumping units 32 are the most powerful domestic equipment items that are the key elements of the booster compressor stations of the Amur GPP. The booster compressor stations are designed for compressing the sales gas before it is supplied to the gas pipeline. Ladoga gas pumping units 32 feature high output and efficiency, reliability under harsh climatic conditions of the Far East of Russia, such as low temperatures and seismicity of up to 8 points.

Commissioning and pre-commissioning are underway at the main gas separation unit on the Amur GPP process line 1. Pre-commissioning is underway at the gas fractionation and NGL treatment unit. Functional tests of chemical analysis system are in progress on process line 2. Pre-commissioning is in progress on process line 3. Target value achievement for gas quality is work in progress at the unit for dehydration and removal of impurities. Oil flushing of the rotating equipment commenced on process line 4. Oil flushing and loop testing of automated process control systems are underway at Ladoga gas pumping units 7 and 8. The main equipment for the compressor station ventilation is installed; installation of the internals and the cold box is nearing completion on process line 5. Installation of the steel structures of the rack is underway on process line 6. Installation of 16 out of 18 industrial waste disposal cells is complete and 70% of road slabs are laid at the solid domestic and industrial waste landfill. Installation of a gas pipeline to two units for thermal treatment of solid waste and a gas pipeline from Amur GPP to solid domestic waste landfill is complete.

Gazprom Pererabotka Blagoveshchensk employees took part in the New Year's Eve charity fair which was held in the Amur GPP plant administration building. Paintings, panels, fluffy toys, Christmas tree decorations, key rings, hairpins, beads, handbags were made by children with disabilities and their parents, as well as folk craftsmen in Svobodny. «New Year's Eve charity events are a good tradition of all Gazprom Group companies. We can do another good deed by participating in the first fair in our new building of the plant administration. It is a special fair because it is the children with disabilities being extraordinary craftsmen who made the creative items for it. The children and their parents put a piece of hope for sympathy, understanding and kindness in their items,» said Sergey Marshansky, Deputy Director General for Human Resources of Gazprom Pererabotka Blagoveshchensk to his colleagues at the opening of the fair. Sergey Marshansky set an example for his colleagues by making his first purchases: fluffy hares being the symbol of 2023. The employees of Gazprom Pererabotka Blagoveshchensk (investor, owner and operator of the Amur GPP) have managed to collect more than 120,000 rubles during the two days of the New Year's Eve charity fair. The proceeds and the warmest congratulations on the upcoming New Year were given to the makers of the crafts — the community of families with disabled children We Are Together in Svobodny.

Loop and functional tests of the equipment, additional leak tests, drying and inerting of the pipelines and units are underway on process line 1 and 2 of Amur GPP. Pre-commissioning is underway at the gas fractionation and NGL treatment unit of process line 1. Zeolite is now loaded into the adsorbers; the fire-fighting system, including the depropanizer and debutanizer sprinklers, is now tested. Additional leak tests, drying and inerting of the pipelines and equipment are nearing completion on process line 3. Construction and pre-commissioning of the unit for dehydration and removal of impurities are complete. Installation and pre-commissioning are underway at Ladoga gas pumping units 7 and 8 on process line 4. Installation of the main steel structures of the rack is underway on process line 5. Main electrical and ventilation equipment is now installed in the indoor switchgear buildings. Erection of the main steel structures and cladding of the compressor building are underway on process line 6. Sandwich-panel cladding of the indoor switchgear building is complete. Installation of 14 out of 18 industrial waste disposal cells, 2 units for thermal neutralization of solid waste, and 2 fire-fighting tanks are complete at the solid household and industrial waste landfill.

Hangars for Ladoga gas pumping units (GPUs) 32 are in construction on process line 6 at Amur Gas Processing Plant. Concreting of their foundations and backfilling are complete there. About 70% of the main steel structures for the hangars have already been installed, and fireproofing is being applied onto them. The last sixth pair of Ladoga GPUs 32 will arrive at Amur GPP site by later this year. Ladoga GPU 32 is the most powerful Russian-made unit manufactured at the Nevsky Plant in St. Petersburg and are the key equipment items of the booster compressor stations at Amur GPP. The stations are designed for compressing commercial gas for the purpose of its further transfer to the Power of Siberia gas pipeline. A total of twelve booster compressor stations will be put into operation at Amur GPP, with two Ladoga GPUs 32 on each process line.

Restoration and pre-commissioning are underway on the licensed units of the Amur GPP process line 1 and 2. Installation of process pipelines on the gas fractionation unit and the natural gas liquid purification unit of process line 1 has been completed; testing of these process pipelines for strength, blowdown, re-assembly and handover for pre-commissioning are underway. Application of insulation onto process pipelines and equipment on the helium fine purification, liquefaction and filling unit of process line 3 is nearing completion. Core scope of construction and installation works on the unit for dehydration and removal of impurities has been completed; pre-commissioning is underway. Pre-commissioning is underway on process line 4: loop testing and re-assembly of static equipment are underway; hot running-in of the air cooler motors has been completed. Welding has been completed, re-assembly and blowdown of the process pipelines and laying of cable lines are underway. Installation and oil flushing are underway at the Ladoga gas compression unit No. 7 and 8. Erection of the main steel structures is underway on process line 5. Welding of pipelines and laying of cable lines are underway at the helium fine purification, liquefaction and filling unit. Erection of the main steel structures and cladding of the compressor room building are underway on process line 6.

Teachers are being honored, wished health, strength, patience, and success in the challenging task of educating the younger generation all over the world. Gazprom class at school 1 in Svobodny too participated in the celebrations. The students recorded their congratulation for their teachers, which we would like to share with you. Staff of Gazprom Pererabotka Blagoveshchensk (investor, owner, and operator of the Amur GPP) are joining the congratulations.

This facility meets all the requirements of both Russian and international environmental standards. The landfill is designed for processing and disposal of waste, including household waste, which will be generated during the operation of the Amur GPP. The process flow sheet provides for wastewater treatment. The territory of 18.5 hectares (the area equal to 26 football fields) will house a receiving area, refuse and wastewater thermal treatment units, a truck scale with a radiation control point, a vehicle disinfection unit, groundwater monitoring wells, portable offices, and much more. The key facilities include 18 isolated cells with the capacity to ensure stable operation of the landfill in the decades ahead.

Yuri Lebedev, Director General of Gazprom Pererabotka Blagoveshchensk LLC acting as the investor, owner and operator of the Amur GPP, discussed the details.

Employees of the Amur GPP are welcomed into new houses in Svobodny yet again. More than three hundred company apartments for the operational personnel of the Amur GPP welcomed new residents. A 9-storey building with 135 apartments was commissioned in the very center of the town of Svobodny at 19/6 Lenina street. All apartments have modern finishing, furniture, plumbing, and household appliances. There is a parking lot, playgrounds for kids, and a sports ground next to the house. Developer Zhiloi Mikroraion LLC has already built eight houses with 602 apartments in Svobodny for the employees of Gazprom Pererabotka Blagoveshchensk LLC acting as the investor, owner and operator of the Amur GPP. Members of the operational personnel of the Amur GPP are also becoming the residents of the new Alekseevsky residential district now. The new residents have received the keys to another 195 apartments with finishing, furniture, and household appliances here. There are children's and sports grounds and a football playing area in the area next to the houses. Developer Zhiloi Mikroraion LLC continues the construction of Alekseevsky residential district for 5,000 people. These are 36 townhouses and 42 apartment buildings with 1,688 company apartments, as well as a school, a daycare facility, a hospital, a community center, and a gym to be built here.

Restoration and pre-commissioning are underway on process lines 1 and 2. Aerodynamic tests of the ventilation system and comprehensive testing of the air conditioning system are nearing completion on process line 3. Hot commissioning is underway at Ladoga gas compression unit No. 5 and 6. Re-assembly of pipelines, application of fireproofing and insulation, and pre-commissioning are underway at the unit for dehydration and removal of impurities from the feed gas. Testing and re-assembly of process pipelines, insulation and electrical works, as well as loop testing of the automation systems are underway on process line 4. Power is now supplied at 10 kV substation according to the project. Installation of pipelines and oil flushing are underway at Ladoga gas compression unit No. 7 and 8. Erection of auxiliary steel structures is underway on process line 5. Erection of the main steel structures and sandwich panels has been completed in 10 kV substation building. Pre-assembly and erection of steel structures are underway on process line 6.

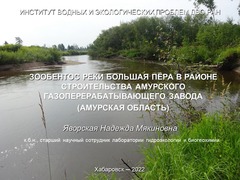

Public Council of Amur GPP and Amur GCC projects assembles in Svobodny One of the main topics for public discussion is the environmental situation in the construction area of the Amur GPP. In early August, a group of experts from the Institute for Water and Environmental Problems of the Far Eastern Branch of the Russian Academy of Sciences conducted a major study of the Bolshaya Pyora River basin. Nadezhda Yavorskaya, candidate of biological sciences and hydrobiologist who studied the Bolshaya Pyora River in the construction area of the Amur GPP, presented her report at the Council meeting. According to the results of the study, there are no negative effects on the river: animals, fish, insects, and other inhabitants feel well, species composition is abundant, and endemics and rare species of hydrobionts have been found. There is no need to take any extra offset measures to reinstate animal habitats or develop any special measures for conservation of any specially protected species. You can listen to the entire report of Nadezhda Yavorskaya, candidate of biological sciences and senior researcher of the Laboratory for Hydroecology and Biogeochemistry at the Institute for Water and Environmental Problems of the Far Eastern Branch of the Russian Academy of Sciences.

Restoration and pre-commissioning are underway on process lines 1 and 2. Pre-commissioning on the major equipment and internal checks of instrumentation in the control room are underway on process line 3. Tests of the foam extinguishing system, sprinkler systems, water discharge of the fire monitor and additional tests of the process pipelines for tightness have been completed at the helium treatment, liquefaction and loading unit. Pre-commissioning on Ladoga gas pumping units No. 5 and No. 6 have been completed. Individual tests of heating, ventilation and air conditioning systems are underway in the indoor switchgear building and transformer substation on process line 4. The substation is ready to receive power. Installation of sandwich panels and the major equipment of the control system is underway in the indoor switchgear building on process line 5. Assembly of the steel and reinforced concrete structures and construction of the driveways and landscaping of the territory are underway on process line 6. Commissioning of equipment has been completed at the sewage treatment facilities; industrial storm runoff is being processed and treated runoff is being supplied for own needs; processes are being tuned in order to achieve their design performance.

Gazprom Pererabotka Blagoveshchensk specialists held several career guidance meetings in the military units located in the surroundings of Belogorsk in the Amur Region. Conscripted servicemen were told about potential employment, benefits and career opportunities at the Amur GPP as well as provided with information about current vacant positions and showed a video about the plant. The event was organized as part of the Far Eastern and Arctic Recruitment Project, which is implemented by the Russian Far East and Arctic Development Corporation (the FEDC) with the assistance of the Ministry for the Development of the Russian Far East and Arctic jointly with the Ministry of Defence of the Russian Federation and the Our Arctic Center of Volunteers and Personnel.

The scientists of the Institute for Water and Environmental Problems of the Far Eastern Branch of the Russian Academy of Sciences (IWEP FEB RAS) are monitoring the status of the environment, plant and animal life in the Amur GPP construction zone. The animal world is studied by a zoologist and a hydrobiologist whilst the plant world is studied by two botanists. According to the scientists, rare species listed in the Red Book of Russia are quite often found in close proximity to the gas processing plant. For instance, an iris ensata, a lilium pumilum, a bush lily, a baikal skullcap, a platycodon grandiflorus and a pulsatilla turczaninovii. «We have been researching for the third year and this is a very short time to make conclusions. Nevertheless, according to our observations, there are no changes in the status of plant communities. Indigenous species feel quite comfortable,» explained Lyubov Antonova, a leading researcher at the Vegetation Ecology Laboratory of the IWEP FEB RAS.

Commissioning works are nearing completion on two Ladoga gas pumping units (GPA) installed on the third process line of the Amur GPP. More than 40 employees of Gazprom Pererabotka Blagoveshchensk acting as the owner, specialists of NIPIGAS acting as the general contractor, as well as specialists of manufacturers are involved in the commissioning works. In the near future, the equipment will be tested in conditions as close to normal operation. The final tests of the equipment were previously performed. This includes checking the operability of the gas turbine control systems and the fire safety systems. The first hot start-ups have already been carried out on one of the units.

Restoration and pre-commissioning are underway on the process lines 1 and 2. Pre-commissioning on the major equipment is underway on the process line 3. Finishing works in the compressor building are nearing completion. Construction and installation works and handover of the systems to commissioning are underway on the unit for dehydration and removal of impurities from the feed gas. Installation and testing of the process piping and insulation of the equipment are underway on the process line 4. Cold box modules assembly and installation of the reflux pumps of the gas separation columns and internals are underway on the process line 5. Installation of the main PCS equipment in the indoor switchgears and transformer substation buildings has completed. Reinforcement of the rack slab is underway on the process line 6. Concreting of the floors and brickwork are nearing completion in the compressor building. Concreting of the walls of the indoor switchgear and transformer substation buildings has completed. Installation of the steel structures, construction of the driveways and landscaping of the territory are ongoing.

Restoration and pre-commissioning are underway on process lines 1 and 2. Heat tracing system is being put into operation, pipelines and equipment are being insulated on process line 3. Loading of perlite has commenced and isolation of equipment and pipelines is nearing completion at the helium liquefaction, treatment and loading unit. Construction is nearing completion at Ladoga 32 gas pumping units 5 and 6. 30 km of process pipelines have been installed, 12 km of pipelines have been tested, and handover of the auxiliary systems to pre-commissioning is nearing completion on process line 4. Insulation of the equipment is in progress and installation of internal contact units has commenced on process line 5. Construction of the racks, concreting of structures, buildings and driveways are in progress on process line 6. Pit is being backfilled and concreting of the rack for the air cooler is complete. Pre-assembly of steel structures has commenced and installation of steel structures for the racks and overpasses is underway. Main landscaping elements have been completed on the territory of the plant administration building.

Mechanical completion of the helium treatment, liquefaction and loading unit construction has reached its highest level. Employees of Azprom Pererabotka Blagoveshchensk (investor, owner and operator of the Amur GPP) and NIPIGAS JSC (general conractor), as well as the representatives of equipment suppliers have started its commissioning.

Start-up of the third process line at the world's largest gas processing plant in the Far East is in progress. Amur GPP is expected to reach its design capacity by 2025. Gas is supplied through the Power of Siberia trunk line from Yakutia and Irkutsk production centres. Ethane, helium and propane are indispensable and rare types of gas extracted from feedstock at the Amur GPP and then exported to China, among other consumers. Large-scale construction in the Far East has given a decisive impetus for development of the region. Professionals from all over the country are coming to this place. Sergey Antsigin watched the work. https://www.ntv.ru/novosti/2707504/

Restoration and pre-commissioning are in progress at process line 1 and 2. Insulation of the process pipelines and equipment is nearing completion at process line 3. Insulation of shut-off and control valves and flanges is underway at the helium liquefaction, treatment and loading unit. Cold start of Ladoga gas pumping units 5 and 6 is underway. Isolation of equipment and installation of the process pipelines are in progress at process line 4. Installation of main steel structures of the overhead structure, pipe and cable racks, as well as process pipelines is underway at process line 5. Equipment insulation has commenced. Concreting of beams and columns has been completed, and installation of main steel structures of the overhead structures and cable racks, main steel structures and cladding of the compressor building are underway at process line 6. Equipment has been installed at the sewage treatment plants, and preparations are underway for their commissioning.

Restoration and pre-commissioning are in progress at process lines 1 and 2. Pre-commissioning and commissioning are continuing, construction and installation of the process pipelines are complete, and handover of the heating tracing systems into operation is nearing completion at process line 3. Installation of the process pipelines, their testing and purging are in an active phase at process line 4. Equipment is being installed at process line 5, in particular, installation of a buffer tank is complete, and installation of the steel structures for cables has commenced. Reinforcement of the beams of the rack for installation of oversize equipment, installation of steel structures of the racks for the compressor building, and concreting of walls are in process at process line 6. Non-licensed units are preparing for a cold start of Ladoga 5 and Ladoga 6 gas pumping units and installation of Ladoga 9–10 units onto their respective foundations. Finishing works of the premises and installation of machines are in progress in the mechanical repair shop.

The fifth pair of Ladoga gas pumping units has arrived at the Amur Gas Processing Plant (GPP). They will be installed on the fifth process line of the plant within the next months. Ladoga gas pumping units are the most powerful domestic equipment items that are the key elements of booster compressor stations of Amur GPP. The stations are designed for compressing commercial gas for the purpose of its further transfer to the Power of Siberia gas pipeline. In total, six booster compressor stations (according to the number of the process lines of the plant) will be put into operation at Amur GPP, and each of them is equipped with two Ladoga units. Ladoga gas pumping units are manufactured in St. Petersburg at Nevsky plant. The units crosses the distance of more than 8 thousand km to Amur GPP within two months on special railway platforms. Temperature of at least positive 5 degrees was maintained in them throughout their journey. Ladoga gas pumping units feature high output and efficiency, reliability under harsh climatic conditions of the Far East of Russia, such as low temperatures and seismicity of up to 8 points. Ten of the twelve Ladoga gas processing units have now been delivered to Amur GPP.

Repair and restoration are underway at start-up complex 1 (process line 1 and 2). Pre-commissioning and commissioning are in full swing at process line 3. Re-assembly of the process pipelines, insulation of pipelines and equipment of the nitrogen rejection unit are nearing completion. Electric heating systems are being put into operation. Construction and installation in the hangars of Ladoga GPU 5 and 6 are nearing completion. Process pipelines are being installed at process line 4, and the insulation of the deethanizer and equipment of the nitrogen rejection unit are in progress. Anti-corrosion protection is being applied to the process pipelines. Construction completion of the priority non-process systems like the sewerage, water supply and fire-fighting water supply systems has been achieved. Concreting of the beam structures is complete on process line 6. Reinforcement of the beams and installation of formwork are underway. Installation of machines in the mechanical repair shop building has commenced.

Amur GPP is one of the largest and most modern gas processing plants in the world. Our plant has become the center of attraction for most qualified professionals in the field of gas processing from all over the country. About 3,200 people will work at the Amur Gas Processing Plant by the time it reaches its design capacity in 2025. Concentration of resources, processes, advanced equipment and highly qualified professionals is like nowhere else. If you also want to join Amur GPP team, send your CV to our recruitment department at ok@amurgpz.ru.

Yuri Lebedev, General Director of Gazprom Pererabotka Blagoveshchensk LLC, was interviewed by Amur.Info news agency. Head of the company acting as the investor, owner and operator of Amur Gas Processing Plant answered the agency’s questions about the training programs of the company, personnel policy, ensuring industrial and epidemiological safety at the site of construction of one of the world's largest gas processing plants.

Restoration and pre-commissioning are in progress at process line 1 and 2. Anti-corrosion coating application on the pipelines is completed; work on their insulation is underway, pre-commissioning and commissioning have entered the active phase. Insulation works on the process pipelines at the helium treatment, liquefaction and loading unit have also reached their end. Ladoga gas pumping units on the same process line 3 are preparing for loop and functional testing. Installation of pipelines has commenced on process line 5. Reflux drum, the first licensed unit, is now installed at process line 6; erection of the pipe rack is also underway. Main construction and installation works are being completed and preparations are underway for commencement of pre-commissioning at the sphere tanks of tank farm 2. Commissioning is underway at the treatment facilities. Installation of utility lines and electrical works are underway in the maintenance and repair workshop.

Eight modern equipment items manufactured in Russia have been installed here in order to train chemical process engineers. Largest chemical process universities in Russia are equipped with similar equipment. The laboratory was furnished at Amur State University with the support of Gazprom Pererabotka Blagoveshchensk.

This information was presented by Aleksandr Grebenyuk, Doctor of Medical Sciences, Professor, Head of Medical Safety of NIPIGAS JSC at the request of Amur GPP/Amur GCC Public Council.

Gazprom Pererabotka Blagoveshchensk has been implementing comprehensive advanced targeted training for young professionals since 2015: from school to university with subsequent employment at Amur GPP. We cooperate with the largest technical universities and colleges of the country located in Moscow, St. Petersburg, Kazan, Vladivostok, Tomsk, Ufa, Tyumen, Irkutsk, and Volgograd. 62 students are studying there as part of their company-backed training. Some of them sent their selfies for the holiday while standing in front of their institutions. We sincerely congratulate our student Yuri Kovalenko who is studying at Amur State University. He has been awarded Gazprom's scholarship! «I am studying in the 3rd year of bachelor's degree in a very promising field of information systems and technologies. I chose this company-backed higher education major in order to find a job at Amur GPP, one of the world's largest gas processing sites, that is very unique in its essence,» says Yuri.

First 12 apartment buildings in the new Alekseevsky residential district in Svobodny have been put into operation today. The solemn ceremony of handing over the keys to the first residents of the district was attended by Yuri Lebedev, General Director of Gazprom Pererabotka Blagoveshchensk LLC, Vladimir Konstantinov, head of the town of Svobodny, and Mikhail Shirokov, General Director of Zhiloy Mikrorayon LLC. Alexey Miller, Chairman of PJSC Gazprom's Management Board, took part in the event via video conference link. The residential district is being built in the north of Svobodny in order to provide сщmpany-backed housing for the employees of the Amur Gas Processing Plant (GPP). 42 five-storey houses and 36 townhouses for 5 thousand residents will be built here in total.

Key events implemented in Svobodny on the initiative and with the participation of public activists.

Interview with Evgeny Baklanov, Deputy General Director for Human Resources at Gazprom Pererabotka Blagoveshchensk LLC, for Amur.Info news agency. https://www.amur.info/news/2021/12/02/197961

New equipment is installed in the technology classes of Chernigovka and Ust-Pyora schools of the Svobodnensky district. These are sewing machines adapted for the school course. Gazprom Pererabotka Blagoveshchensk provided the necessary funds to buy this equipment. Students of the 9th grade of Chernigovka school were the first to appreciate the new machines: they sewed flags for the National Unity Day. Moreover, both girls and boys are proficient in sewing at this school. «It is important that the children leave the celebration with the feeling that they can do a good thing. An example of a good deed was the assistance in the procurement of equipment for our school by Gazprom Pererabotka Blagoveshchensk,» says Natalia Litvinenko, technology teacher. «Professionals who own technologies and processes are the main people in any production process. That's what they're called: chief process engineers. They can handle any task, because they know the answer to the key question „How to do it?“. I wish you that you are able to handle any tasks in your life,» Yuri Lebedev, General Director of Gazprom Pererabotka Blagoveshchensk LLC, congratulated the schoolchildren on the holiday celebrations. Two similar sewing machines were also purchased for the Ust-Pyora school technology room. Chemistry and physics classrooms in both schools, are now equipped with all the necessary laboratory equipment for practical classes with the help of Gazprom Pererabotka Blagoveshchensk.

Correspondent Pavel Orlov visited the Amur Gas Processing Plant and the Chayandinskoye field and the factories in Kaliningrad and St. Petersburg in order to explain how helium without which scientific and technological progress is impossible today is produced.

As Andrey Belousov, Gazprom Pererabotka Blagoveshchensk LLC Deputy Director General, described, the company uses this road on the basis of concession agreement. Since 2018 the road marking was applied on the pavement twice a year. The section of the road near the Amur GPP site is known for its intense traffic, so that it was decided to add a yellow stripe to increase the visibility of road marking during winter time and to decrease the possibility of accidents. For the moment, yellow section of the marking is finished, the works on white marking elements are underway. The works are to be finished on the next week. Gazprom Pererabotka Blagoveshchensk is the investor, owner and operator of the Amur GPP. The plant site is featured by its vast infrastructure, including 27 kilometers of access roads, Zeya river jetty and around 40 kilometers of railways.

This heat exchanger is needed for heat recovery of nitrogen-helium mixture as part of helium production process. It was the third and the last heat exchanger to be installed at Amur GPP (one heat exchanger for each helium unit). Mass of single heat exchager — around 50 tons, length — 16 m, diameter — 1.8 m, heat capacity — 8.5 MW. The equipment was manufactured using capacities of Linde Severstal (a joint venture of Severstal and Linde GmbH) in Saint-Petersburg, with assistance of Gazprom. The first heat exchanger was delivered and installed at Amur GPP in 2018, the second — in 2019. First heat exchanging helium unit was put into operation in September 2021.

Teachers’ Day: Our digest of educational programs in Svobodny, implemented with assistance of Gazprom Pererabotka Blagoveshchensk (Amur GPP investor, owner and operator), in the video.

The first and second process lines of the Amur Gas Processing Plant have been put into operation. The first helium extraction, liquefaction and loading unit with a capacity of 20 million cubic meters of helium per year has been put into operation. Shipment of helium from the Amur Gas Processing Plant to the world's largest helium hub of Gazprom in Vladivostok has commenced. 89% of the process pipelines have been installed on the third process line, and proper strength tests are being conducted thereof. Commissioning is nearing completion at the substation of the NGL and helium separation units, and preparations are underway for power supply. Welding and strength tests have been completed on the units of the second helium plant, and the systems are being prepared for handover to commissioning. Cold block modules are being assembled at the fifth process line. Building cladding is in progress. Fire protection is being applied on the main steel structures and foundations for large-sized equipment are being erected at the sixth process line. Navigation of 2021 has been successfully completed. 51 units of large-sized heavy cargo with a total weight of over 5.5 thousand tons were delivered.

The last batch of equipment planned for navigation in 2021 for construction of the Amur Gas Processing Plant (GPP) has been delivered to the jetty of the plant. Four tanks for storing liquefied helium, feed gas expander, heat pump compressor, its motor, as well as other equipment have arrived via the river Zeya. Gas separation columns for the fifth process line are the most significant items in 2021 navigation. For example, the weight of the demethanizer is 870 tons, and its length is 88 m. The first nitrogen rejection column with a length of more than 58 meters weighs 883 tons. The length of the second one is 63 meters, and its weight is more than 400 tons. These columns are the key equipment of the gas separation unit which will extract valuable fractions from the multicomponent natural gas coming via Power of Siberia gas pipeline from Chayanda and Kovykta fields. 51 units of large-sized heavy cargo with a total weight of more than 5.5 thousand tons have bee delivered by two sea vessels to the Russian port De-Kastri in total during 2021 navigation period. After transshipment to 8 tug and barge towing arrangements, the large-sized heavy cargo was sent along the Amur and Zeya rivers to the temporary jetty of the Amur Gas Processing Plant. Navigation plan for 2021 has been implemented in full.

Please watch the speeches by Alexey Miller, Chairman of the Management Board of PJSC Gazprom, and Yuri Lebedev, General Director of Gazprom Pererabotka Blagoveshchensk LLC. Full record of the broadcast is available on the website of Russian President Vladimir Putin who took part in the event via a video link. http://www.kremlin.ru/events/president/news/66585

Record of the solemn ceremony of the launch of the second process line and the helium unit of the Amur Gas Processing Plant, as well as the helium hub of PJSC Gazprom. The event was attended by President of the Russian Federation Vladimir Putin and Chairman of the Management Board of PJSC Gazprom Alexey Miller. The ceremony was broadcast by Russia-24 TV channel.

Preparations for the launch of the second process line are nearing completion. Mechanical availability of the helium fine purification and liquefaction unit 1 has been reached. Installation of thermal insulation of the columns is being carried out, pipelines at the ethane, NHL and nitrogen and helium mix separation unit at process line 3. Electrical works have been completed at the substations of the gas separation unit and helium fine purification and liquefaction unit 2. Substations are being prepared for inspection by Rostekhnadzor. Large-capacity equipment delivered in 2021 navigation for the fifth process line is being delivered and erected. The largest equipment has been installed: the methane extraction column (demethanizer) and two nitrogen rejection columns.

Total weight of 26 cargo units is more than 1,200 tons. These include the vessels and parts of the cold box for raw gas for the gas separation unit. Handling works are performed at the jetty with use of two cranes with 1,350 t capacity. Large-sized and massive parts of the cold box will be delivered to the construction site of the plant using the self-propelled modular trucks. In order to ensure proper safety, transportation will be carried out mainly at night at a pedestrian speed. The cold box is designed to cool the natural gas entering the plant before being fed to the gas separation columns and is an important element of the cryogenic gas separation complex for process line 5. Earlier, four similar cold boxes for raw gas were installed on the first four process lines of the Amur Gas Processing Plant. In total, during the summer navigation of 2021, it is planned to deliver 51 units of equipment with a total weight of around 5.6 thousand tons to the construction site of Amur GPP.

Reporters of Vesti-Amur Region program are following the construction of the Amur Gas Processing Plant very closely. Here is a recent report about installation of the gas separation columns on process line 5 of the Amur Gas Processing Plant built under Gazprom's Eastern Gas Program. It took a whole special operation to deliver and install the largest equipment that came in in this year’s navigation period. See the details in the report of Viktoria Sytenko, correspondent of Amur state broadcasting company. https://gtrkamur.ru/

Demethanizer weight is 870 tons, the length is 88 m. The first nitrogen rejection unit with a length of over 58 meters weighs 883 tons. The length of the second one is 63 meters, and it weighs over 400 tons. The installed columns are the key equipment of the gas separation unit which will extract valuable fractions from the multicomponent natural gas received via the Power of Siberia gas pipeline from Chayanda and later Kovykta fields. The columns were delivered from the jetty on the Zeya river to the construction site of the Amur GPP using self-propelled modular transporters. In order not to interfere with the traffic to ensure proper safety, transportation was carried out mainly at night at a speed of 5 km/h. Cranes with a lifting capacity of 600 and 1600 tons were involved in installation of the columns on the fifth process line of the Amur GPP.

By the end of July, the mechanical completion of the main gas separation unit was achieved. Transportation and installation of heavy-lift equipment for the fifth process train was delivered and installed during the 2021 navigation. Ladoga-32 gas compression unit of the third train was subject to alignment, Ladoga-32 subsystems were under testing. Water circulation pump station equipment went through individual tests. Water treatment facilities — water treatment unit commissioning. The construction of a 7-storey administrative building for 285 employees continues. The construction of a repair shop of 18 thous. m2 area is underway.

The investor and the owner of Amur GPP — Gazprom Pererabotka Blagoveshchensk — provided funds for rehabilitation of Yasmin, suffering from infantile cerebral paralysis, as part of a charity program in cooperation with Amur department of Russian Children Care Fund. Gazprom Pererabotka Blagoveshchensk found out about Yasmin and a couple of kids from Svobodny, having several diagnoses, during Krylia charity event. As result, the company purchased stair-climbing chairs for Maria Gevorgyan and Maxim Pavlov, while Yasmin Sarbarova was presented with a certificate for courses of therapeutic horse riding and knesiotherapy. Since the beginning of 2021 Gazprom Pererabotka Blagoveshchensk transferred over 3 million roubles for support of physically challenged children and children being in difficult situations. In the last year, the company implemented charity programs for total value of 21 million roubles.

These columns are the largest equipment to be delivered during this year navigation. Columns are to be installed on the fifth train of the plant. How it is planned to supply the columns from the jetty to the site and when — all of it is in report of Vesti. https://gtrkamur.ru/news/2021/07/29/175684

During the last month, they’ve been working on the first train of the plant and in central laboratory. Students have studied the low-temperature processes and operation of cryogenic equipment for liquefaction and extraction of helium, methane and other hydrocarbon gases.

The largest equipment for the fifth process line is delivered to the jetty of the Amur Gas Processing Plant (Amur GPP): methane extraction column (demethanizer) and nitrogen rejection unit. These are the largest pieces of equipment to be delivered to the Amur GPP during the summer navigation of 2021. Demethanizer weight is 870 tons, the length is 88 m. Nitrogen rejection unit with a length of over 58 meters weighs 883 tons. Handling works are performed at the Amur GPP jetty with use of two 1350-tons capacity cranes. Equipment is to be transported to the site by crane trucks and self propelled modular transporters. In total, during the summer navigation of 2021, it is planned to deliveer 37 units of equipment with a total weight of around 5.6 thousand tons to the construction site of Amur GPP. Four tug/barge arrangements will be used for transportation of equipment along Amur and Zeya rivers.

Six years of construction in six minutes of video! The story of construction of Amur GPP. In 2015 the first pile of the site was driven, in 2017 the first foundation was laid. At the same time transport infrastructure, such as roads, bridges, railways, jetty, was under construction. The first heavy-lift equipment for the first train was delivered during 2018 navigation. In 2019 Amur GPP began to turn into the plant as we know it, when giant separation columns and cold boxes were installed on three trains. The first train was put into operation on June 9, 2021. The ceremony was attended by Vladimir Putin, the president of the Russian Federation, and Aleksey Miller, the Chairman of Gazprom PJSC Administration Board.

Thousands of lamps now illuminate the plant and each of its enormous separating columns, so that the silhouette of the Amur GPP could be seen in day and night.

The second train of Amur GPP is under preparation for hot commissioning. The second pair of Ladoga gas pumping units of the booster compressor station is ready for cold start. Foundation for installation of heavy-lift equipment at the fifth train is completed. The 1600 t capacity ring crane for installation of gas separation columns is installed. Structures of buildings and pipe racks are under installation. As for the third heilum fine purification unit, the structure for main equipment and helium filling tanks is under installation. The raw gas furnace of the second gas dehydration and purification unit has been fired.

Yuri Lebedev, Director General of Gazprom Pererabotka Blagoveshchensk LLC, has held a meeting with students, during which he noted: “It is a great opportunity to get familiar with features of the plant with help of highly skilled professionals, which will act as your mentors during your internship. Besides, it is also a great opportunity to get the experience of working on such an advanced plant, as Amur GPP”.

The second group of students of Department of Engineering and Physics with majors in Chemical Processes have graduated. In this year the State Examination Board was headed by Yuri Lebedev. 14 chemistry students have successfully defended their degree theses, prepared with taking into consideration the needs of the leading enterprises of the chemical industry, and first and foremost — the needs of Amur Gas Processing Plant. Seven of the graduates are going to build their careers on Amur Gas Processing Plant.

Buildings of the administrative and amenity complex on the territory of the plant with rest rooms and meals, showers, ergonomic furniture and everything necessary for productive work are being gradually put into operation. For example, the interiors of the recreation area in the central operator room of the Amur Gas Processing Plant are made to measure: one can drink tea or coffee, have a snack, relax in comfortable chairs in this comfortable and stylish room. «It is very important to create unhindered comfortable working conditions for the professionals for reliable operation of the modern giant plant,» says Danis Fayruzov, Chief Engineer and First Deputy General Director of Gazprom Pererabotka Blagoveshchensk LLC.

Dozens of seedlings were planted by the employees of Gazprom Pererabotka Blagoveshchensk together with students of Gazprom class near the Svobodny school 1 in May. Victory Alley was created in 2020 for the 75th anniversary of the Victory in the Great Patriotic War on the initiative of the employees of the Amur Gas Processing Plant. Last year, about 300 different types of trees and shrubs were planted: thuja, viburnum, dasiphora, Ussuri acacia, Amur cork tree, and others. In 2021, the Memory campaign was continued by planting 100 seedlings of red mountain ash, linden, cherry, hydrangea, and mock oranges. The campaign was supported not only by the students of the second team of the Svobodny Gazprom class, but also by the citizens. Large-scale landscaping in Svobodny takes place annually in the spring within the framework of EKO-Svoboda volunteering project initiated by the Public Council of the Amur GPP/GCC. All seedlings are purchased in Amur nurseries.

With the participation of the representatives of the developers of the process equipment, specialists in the field of gas processing work out their practical skills of starting up the Amur GPP units at the on computer training complexes. More than fifty employees of the plant have already completed training and improved their skills.

This has made it possible to significantly improve the nutrition in the institution, to feed the students in a balanced way and with maximum benefit.

Do you know what you can use to fill up a KAMAZ truck intended for transportation of liquefied helium which will be produced at the Amur Gas Processing Plant, in addition to gasoline and diesel? And what does Africa have to do with it? In the new episode of Do You Know That? mini-series, we will talk about methane as fuel, its connection with KAMAZ Master team and its significance for the environment.