History

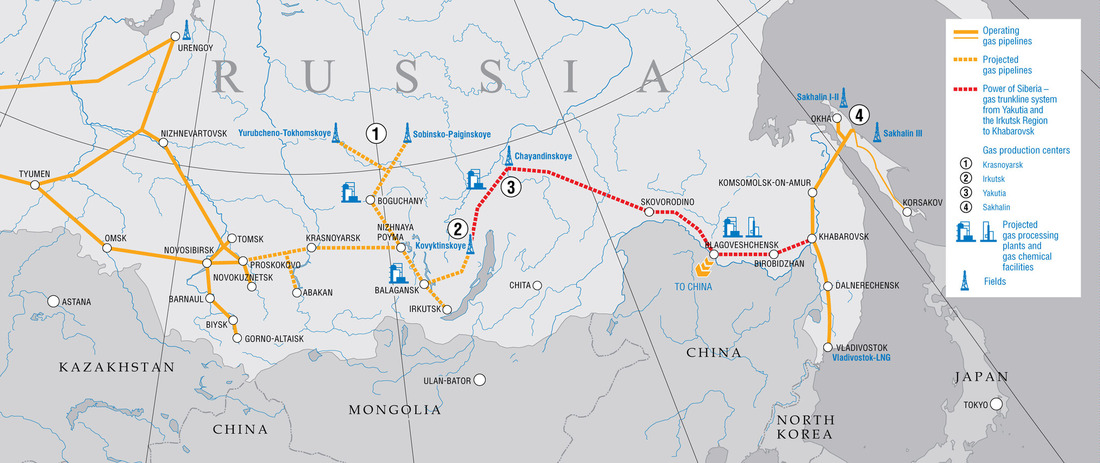

Back in September 2007, the State Program for Establishing a Unified System of Gas Production and Transportation and Gas Supply in Eastern Siberia and the Far East was established under the order of the Russian Ministry of Industry and Energy with account for potential gas exports to the markets of China and other countries in the Asia Pacific region (Eastern Gas Program). The Russian Federation Government instructed PJSC Gazprom to coordinate the activities related to the Program. The company formed an extensive resource base in the Russian East with new gas production centers which allowed to implement large-scale infrastructure projects.

In 2012, PJSC Gazprom made the investment decision with regard to field infrastructure development for the Chayanda (Yakutia) and Kovykta (the Irkutsk region) fields, Power of Siberia gas pipeline construction, as well as the construction of the Amur GPP in the Amur region.

In May 2014, PJSC Gazprom and China National Petroleum Corporation signed a sales and purchase agreement for gas to be supplied via the eastern route.

Russian President Vladimir Putin, PJSC Gazprom Management Committee Chairman Alexey Miller and President of China National Petroleum Corporation Zhou Jiping.

In May 2014, the order on implementation of PJSC Gazprom's investment projects was signed in order to supply gas to China and an integrated action plan was approved. The plan included development of the Yakutsk and Irkutsk gas production centers, construction of the Power of Siberia gas pipeline and the Amur Gas Processing Plant to extract valuable components (helium and ethane, in particular) from gas.

On July 3, 2014, an entry was made in the Unified State Register of Legal Entities on establishment of Gazprom Pererabotka Blagoveshchensk LLC, the investor and owner of the Amur Gas Processing Plant construction project. Gazprom Pererabotka Blagoveshchensk LLC is a subsidiary of Gazprom Pererabotka LLC and member of Gazprom Group.

On October 14, 2015, the President of the Russian Federation Vladimir Putin launched the project, and the first “golden pile" was sunk during the ceremony.

On February 29, 2016, Gazprom Pererabotka Blagoveshchensk LLC was assigned with the role of the Amur Gas Processing Plant operator under the order of PJSC Gazprom.

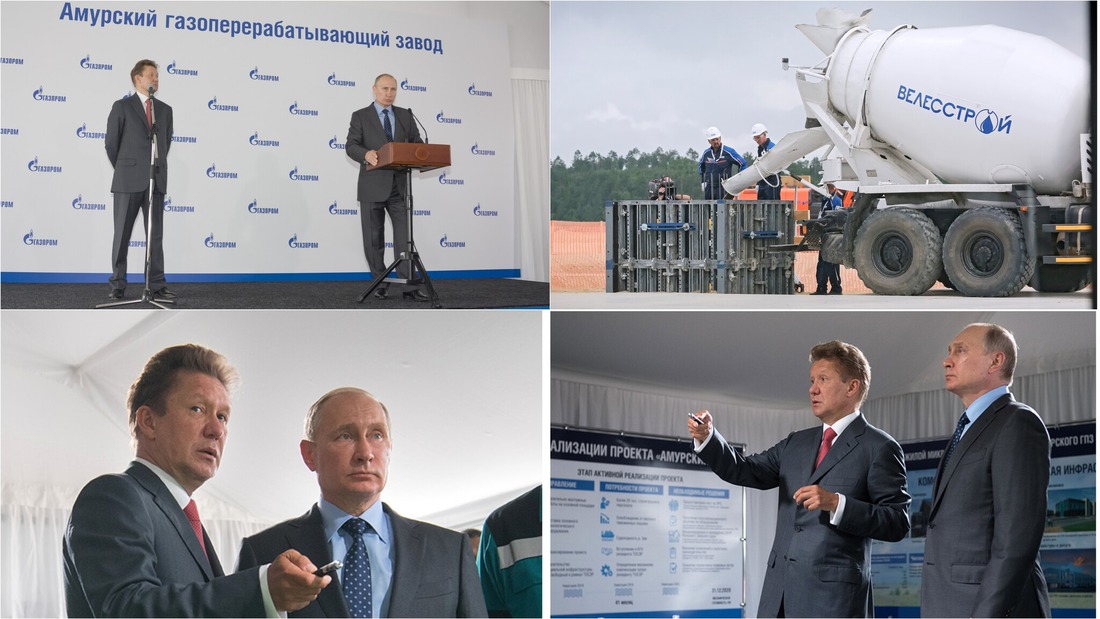

On August 3, 2017, the first foundation of the Amur Gas Processing Plant was laid.

The event was attended by the President of the Russian Federation Vladimir Putin and Chairman of the Management Committee of PJSC Gazprom Alexey Miller.

From 2015 to 2018, the site preparation was completed, infrastructure was prepared for full-scale construction: 27 km of access roads were commissioned, a temporary jetty on the Zeya river was built, temporary shift camps with all the infrastructure were built, a 17.5 km long railroad track from the Trans-Siberian railway to the plant site was built.

In December 2019, Gazprom and Gazprom Pererabotka Blagoveshchensk signed a deal to raise project financing totaling EUR 11.4 billion for the Amur GPP construction. The funds are provided by 22 European, Asian and Russian banks.

From 2018 to 2020, the key process facilities of the Amur GPP were built. As of January 2021, the four process lines of the Amur GPP were fully equipped with the key large-sized units.

In January 2021, large-scale commissioning began at start-up complex 1 (the first and second process lines, the first helium production and liquefaction unit). Highly skilled professionals of Gazprom processing enterprises from Astrakhan, Orenburg, Salavat, and Surgut were involved in commissioning of the Amur GPP: process unit operators, pump and compressor operators, operators of various gas processing fields, foremen and engineers, including in the field of energy and electronics, debugging and testing, automated process control systems, and instrumentation.

Employees of Gazprom subsidiaries, including Astrakhan, Orenburg, Salavat and Surgut processing companies.

On June 9, 2021, a solemn ceremony was held to launch the first process line of the Amur GPP with the participation of President Putin. Implementation of such a large-scale project in the field of processing is one-of-a-kind in the history of the Russian gas industry.

In September 2021, first of three helium production, liquefaction and loading units commenced their operation at the Amur GPP. Its capacity is 20 million cubic meters of helium per year. Shipment of helium from the Amur GPP to the world's largest Vladivostok Logistics Centre of Servicing Helium Containers (hub) for transporting liquid helium to the world market commenced.

Phased start-up of the remaining lines of the Amur GPP is aligned with development of PJSC Gazprom's capacities in Yakutia and the Irkutsk region. The project involves around 1,000 equipment vendors and over 500 contractors. More than 35 thousand construction workers were involved at the Amur GPP site at peak times.

First half of 2023 saw pre-commissioning and commissioning of process lines 1, 2 and 3 of the Amur GPP.

Safety systems of the main gas separation unit were also improved, specifically, the automatic fire alarm, fire extinguishing and gas contamination monitoring systems, ultra-sensitive laser system for detecting methane leaks, and an expanded process surveillance system were installed, debugged and tested.

Process line 1 was put into commercial operation and reached its design process mode back in August 2023.

Process line 1 generated its first commercial products with design specifications in September 2023. Helium treatment, liquefaction and loading unit 1 began shipping highly-purified (99.9999%) liquefied helium. Gas fractionation and NGL purification unit generates commercial products under design specifications.

Process line 3 was put into operation in its design process mode, with the main gas separation unit producing commercial gases with design specifications and helium treatment, liquefaction and loading unit 2 seeing its hot commissioning.

Process line 2 was put into routine process operation in November 2023. Helium treatment, liquefaction and loading unit 2 on process line 3 began shipping highly-purified (99.9999%) liquefied helium.

In December 2023, three Amur GPP process lines out of six were in operation and produced commercial gases, with two out of the three treatment, liquefaction and loading units shipping liquefied helium on a regular basis. A total of over 100 isothermal containers with this cryogenic product-which is more than 400 tons-were shipped to Russian and worldwide consumers in 2023.

Plant construction was also in progress across 2023: preparations for commissioning were in full swing on process line 4 and construction was underway on process line 5 and 6.

As of December 31, 2023, the Amur GPP construction progress reached 90.93%.

Enlarged photo (JPG, 3 MB)