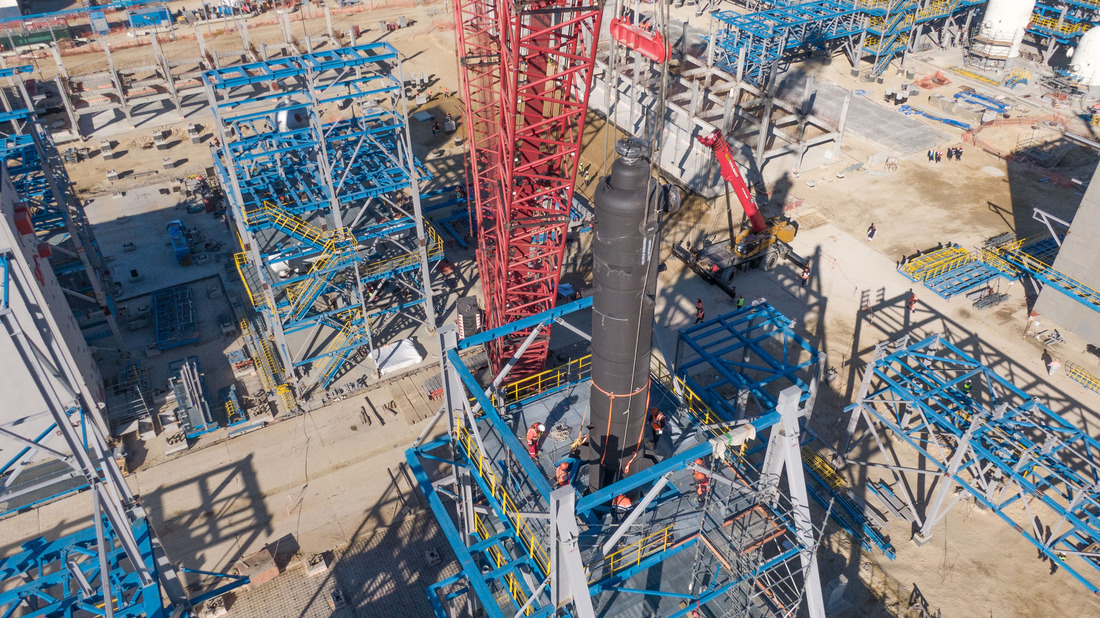

Completion of installation of Russian heat exchangers at the Amur GPP

A spiral-wound heat exchanger is installed at the third helium purification, liquefaction and loading unit of the Amur GPP. This heat exchanger is needed for heat recovery of nitrogen-helium mixture as part of helium production process.

It was the third and the last heat exchanger to be installed at Amur GPP (one heat exchanger for each helium unit). Mass of single heat exchager — around 50 tons, length — 16 m, diameter — 1.8 m, heat capacity — 8.5 MW.

The equipment was manufactured using capacities of Linde Severstal (a joint venture of Severstal and Linde GmbH) in Saint-Petersburg, with assistance of Gazprom.

The first heat exchanger was delivered and installed at Amur GPP in 2018, the second — in 2019.First heat exchanging helium unit was put into operation in September 2021.

«Great heat exchanging capacities are ensured due to having lots of small tubular spirals, that provide the heat exchanging area of over 1500 square meters, which is equal to around a quarter of a football field. One of the features of the design is that the spirals are designed for a greater temperature drop, than usual heat exchanging elements, of from 45 to 450 degrees, which fits the purposes of helium production. Any other type of heat exchangers can withstand a temperature drop of only 250 degrees maximum» — Danis Faizurov, Chief Engineer and Gazprom Pererabotka LLC Director General Fist Deputy explained.

Background:

The Amur GPP is to be one of the world's largest natural gas processing plants with its annual capacity of 42 bln of cubic meters of gas. Under full load, the Amur GPP is to provide annually around 2.4 mln tons of ethane, 1.5 mln tons of LPG, 200 tons of pentane-hexane fraction and 60 mln cubic meters of helium, which is highly demanded by high-tech industries. The main consumer of ethane and LPG from the Amur GPP is going to be Amur Gas Chemical Complex (joint SIBUR and China's Sinopec project).

To date, the first two lines of the plant have been put into operation, as well as the first helium purification, liquefaction and packaging plant.

Gazprom Pererabotka Blagoveshchensk LLC (member of Gazprom Group) is the investor, the owner and the operator of Amur GPP. Construction is managed by JSC NIPIGAS.

Enlarged photo (JPG, 916 KB)